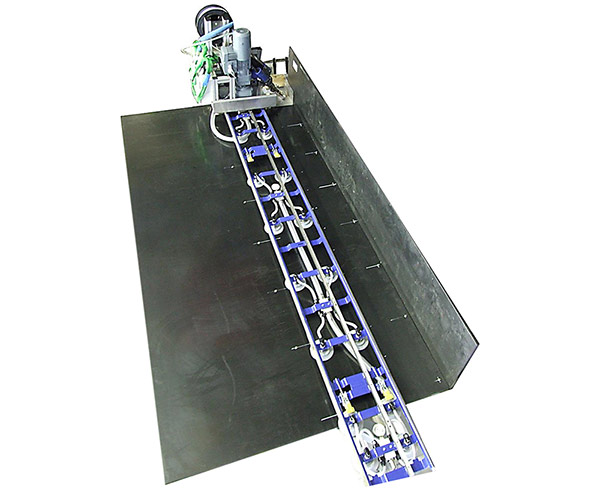

Linear Welding System

Production of rectangular tank construction

We can of course adapt this machine to your individual needs! Contact us now!

| Technical Data:

|

LWS |

|---|---|

| Seam length: | 0 to 13,000 mm

|

| Extruder output capacity: | 2.5 kg/h (PE)

|

| Welding speed: | 0.1 to 1.6 m/min adjustable) depending on seam volume

|

| Rail length: | 0.5 m to 4 m welding unit 2 m

|

| Weight approx.: | 70 kg

|

| Fine angle adjustment of extruder (before welding)

|

|

| Lateral tracking for extruder during welding | |